Circular economy at URSA

At URSA we take our waste management as seriously as we take our materials production. We aim to establish ourselves as pioneers in circular economy practices.

Targets

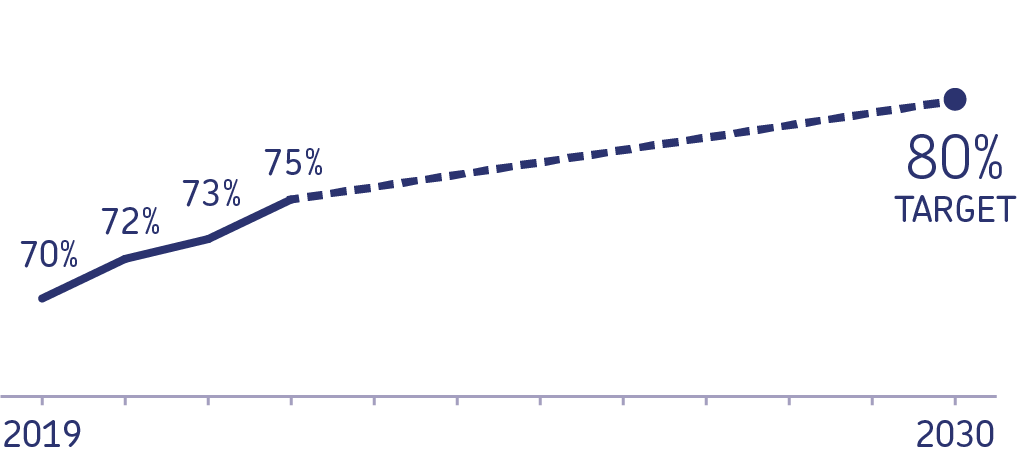

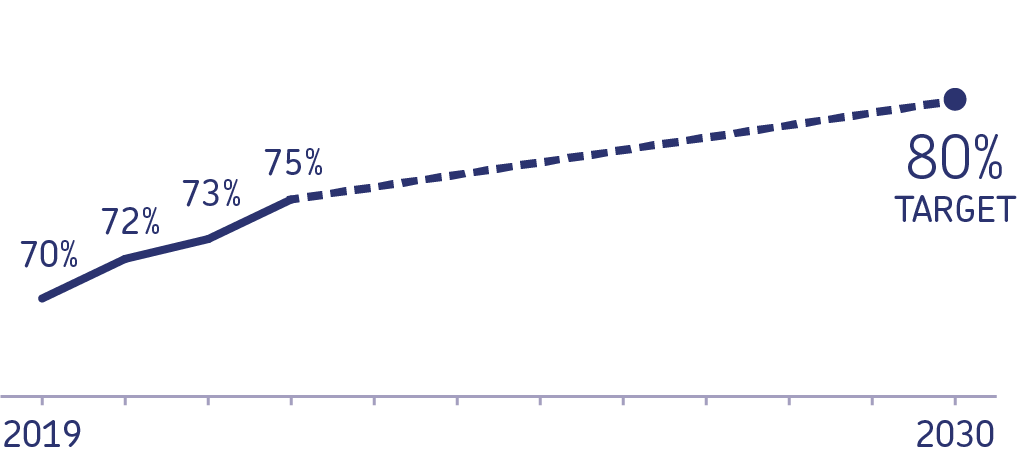

Use of recycled material on URSA’s products

Mineral wool

We already use 75% recycled products. We reprocessed glass in to the manufacture of its mineral wool products and we aim of increase that figure to a minimum of 80% by 2030.

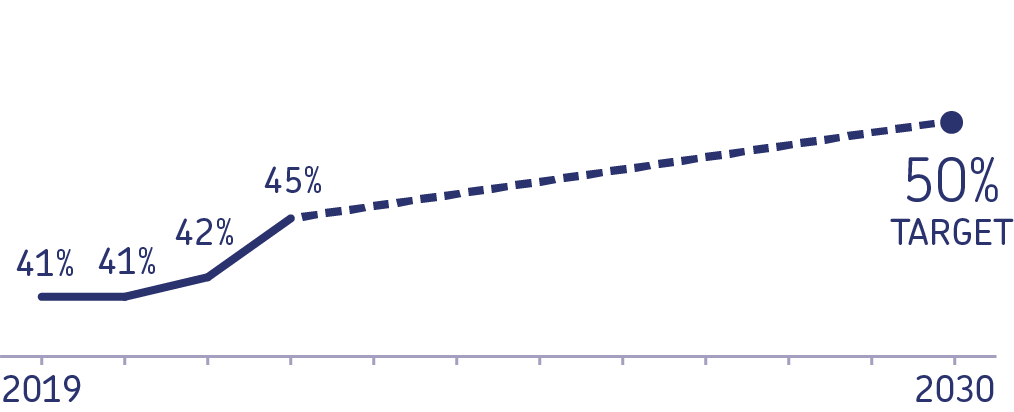

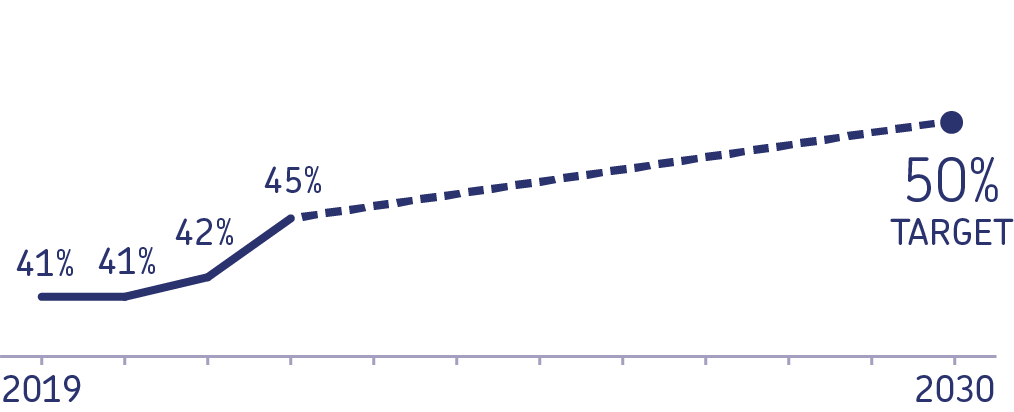

XPS

We already use 45% recycled polystyrene products. We source to the manufacture of our XPS products. We aim increase that level to a minimum of 50% by 2030.

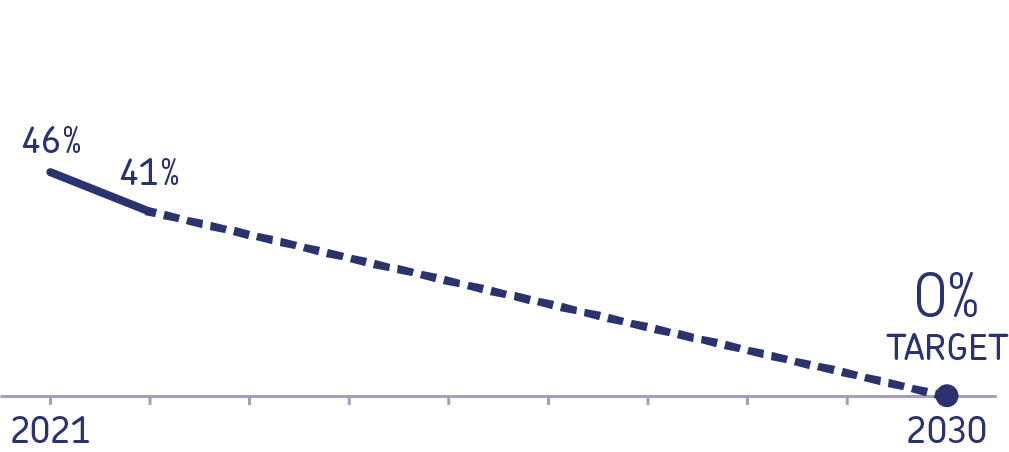

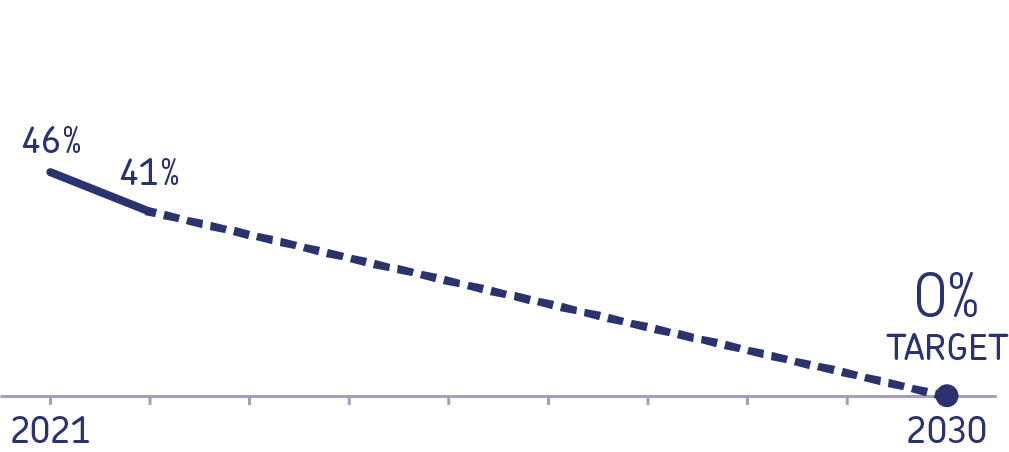

Zero glass mineral wool and XPS internal leftovers to landfill by 2030

Circular economy at URSA

Take-back service

URSA is working with customers and partners to collect the leftovers to give at construction and demolition sites a second life.

Benefits

- Stronger customer relationship.

- Financial savings (lower cost of used material vs virgin raw material).

- Reduction of environmental impacts (avoid landfill).

Related news

Making open plan offices work – insulation, the critical ingredient

Open spaces have been a growing trend since 1990. But they are not always the most suitable option depending on where you are in the world. The sustainability, comfort and profitability of a business space or open space home will depend on insulation, climate and location.